Benefits of Implementation

By implementing IoT and monitoring systems, we simultaneously enhance equipment efficiency and quality competitiveness.

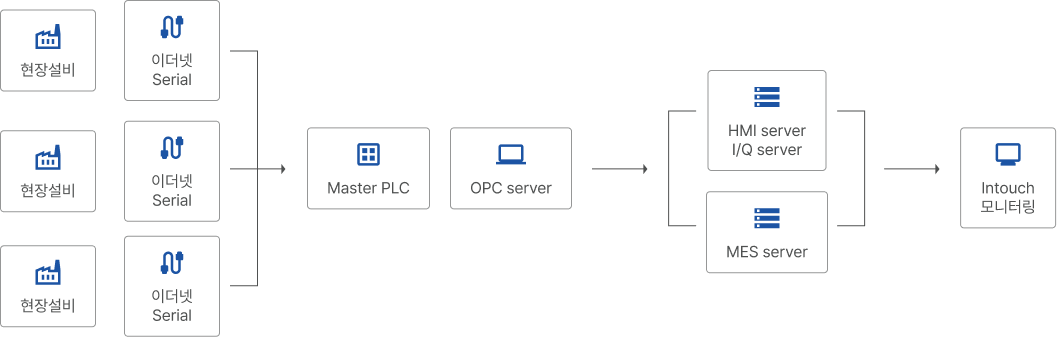

24-Hour Equipment Monitoring and Control

Allows quick response through alarm notifications when abnormalities are detected.

Equipment status is recorded for future analysis and discussion of countermeasures.

Redundant data management ensures consistent equipment control, reducing risks while maintaining optimal conditions and safe operation.

Provides automated equipment operation and an advanced user graphic interface.

Maximizing energy savings through efficient operation of equipment and facilities under various external and internal load conditions.

By early detection of system abnormalities, the convenience of equipment and facility management is maximized, while centralized control and monitoring minimize management costs.

Based on established technologies in the Donghwa system field, and considering future technological advancements, we adopt a structure that allows functional enhancement or performance improvement simply through network expansion and tag addition when new features or load requirements arise, enabling comprehensive and integrated system management.

Monitor equipment utilization, energy consumption, and environmental data at a glance through IoT,

We implement a systematic smart factory, covering everything from maintenance to energy savings.