Smart Factory, now a must, not a choice

Automation is essential. Get the perfect solution designed for your factory.

Factory

Smart Factory

- Virtual Space

- Real space

Not only can you automate the entire production process,

but you can also achieve improved quality, increased productivity, reduced energy consumption, and lower labor costs.

Non-support

270.3

278.3

after 2years

Support

272.9

304.5

after 2years

Average Revenue Trend (₩100 Million)

Non-support

5.9

8.9

after 2years

Support

5.8

11.8

after 2years

Average Export Trend (₩100 Million

*IoT and AI-Based Smart Factory Technology Development Strategy and Market Outlook,” Daeco Industrial Research Institute, 2019

KULS Smart Factory Solutions

Chosen by Numerous Small

and Medium-Sized Manufacturers

SOLUTION.01

Customized Smart Factory Implementation

Providing Optimal Solutions Tailored to Factory Size and Industry

SOLUTION.02

One-Stop Support for the Entire Process

Responsible for Everything from Design to Implementation to Maintenance – A to Z Operation

SOLUTION.03

Government-Supported

Project Consulting

Project Consulting

We Support You from Complex Application Procedures to Securing Funding.

SOLUTION.04

Experts in Manufacturing + IT Integration

IT experts specialized in manufacturing and logistics systems design.

SOLUTION.05

On-Site Support &

Efficient Issue Resolution

Efficient Issue Resolution

On-Site Support and Responsible Maintenance

MES / POP / SPC / WMS

Smartfactory solution

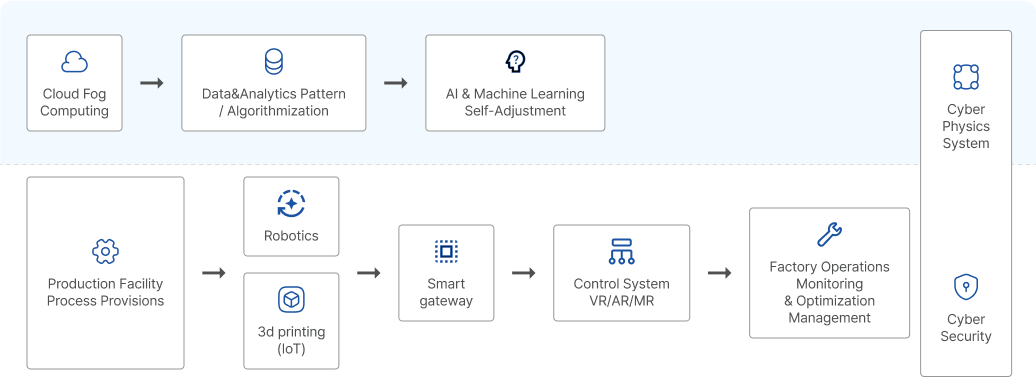

KULS’ factory automation solutions realize digitalization

and optimization of production sites through MES, SPC, POP,

data management systems, and inventory management systems.

View

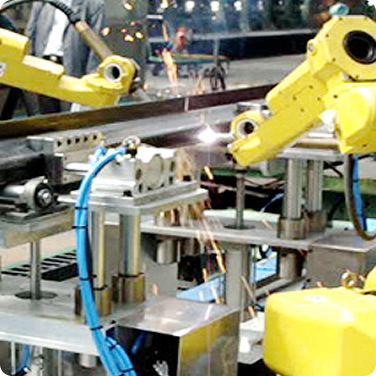

FA Automation Robots / Autonomous Vehicles

Factory Automation Solutions

With KULS ICT, implementing innovative automation systems

becomes even easier with the adoption of robotic automation.

View

HMI / DAS / CIM /PLC

IoT Monitoring Solution

for Equipment Integration

Real-time visualization of manufacturing processes,

analysis of downtime factors, and predictive maintenance systems help maximize productivity and equipment efficiency (OEE). On-site interfaces through HMI and PLC, data acquisition via DAS, and CIM integration enable seamless connectivity with higher-level systems such as MES and ERP.

View

analysis of downtime factors, and predictive maintenance systems help maximize productivity and equipment efficiency (OEE). On-site interfaces through HMI and PLC, data acquisition via DAS, and CIM integration enable seamless connectivity with higher-level systems such as MES and ERP.

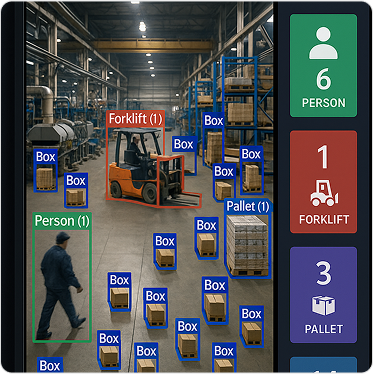

APS, Digital Twin, Object Recognition

AI-Based Intelligent Production Planning

& Simulation Solutio

By integrating APS, Digital Twin, and object recognition technologies,

precise production planning and process simulation are implemented

based on real-time factory data, enabling reduced manufacturing lead times

and optimized resource utilization.

View

Introduction procedures

How It Works

Free Consulting & On-Site Visit

Customized Design & Feedback Implementation

Support for Government-Supported Project Applications

Equipment & System Implementation

Close Monitoring & Optimization

Case & Testimonials

Our Clients

Customer Trust Drives KULS’ Growth.

Considering Building a Smart Factory?

Start Your Tailored Smart Factory the Easy Way!